Wood-Plastic Composites (WPC) have revolutionized the decking industry by offering a sustainable and low-maintenance alternative to traditional wood. Over time, WPC technology has evolved from first-generation single-layer boards to advanced co-extrusion types. This article provides an in-depth comparison between these two generations, examining their composition, performance, aesthetics, maintenance requirements, cost implications, and environmental impact.

Composition and Manufacturing Process

First-Generation WPC

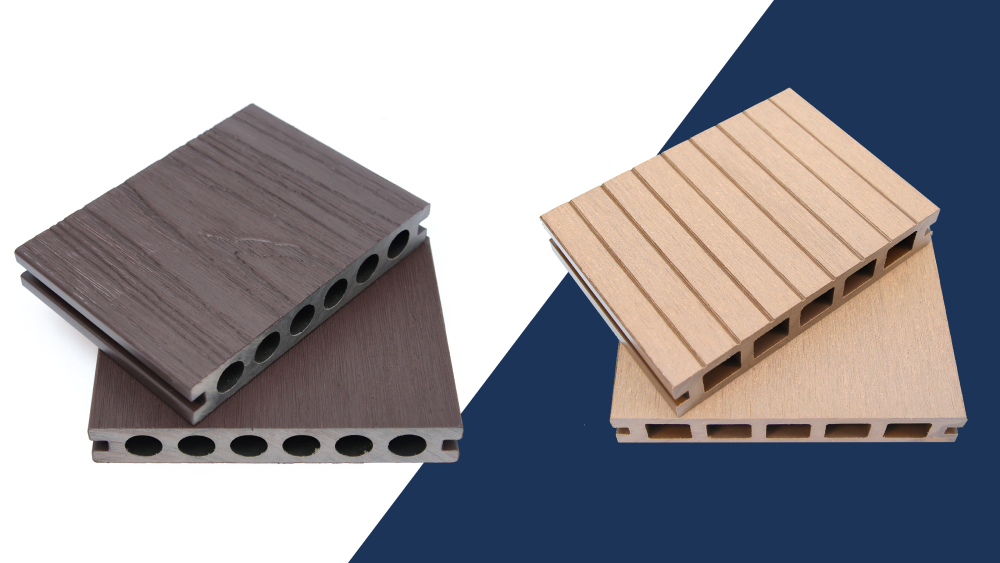

First-generation WPC products consist of a homogeneous blend of wood fibers and thermoplastic materials, such as polyethylene or polyvinyl chloride. These boards are extruded without additional protective layers, resulting in a single-layer structure. However, the lack of a protective cap leaves the material exposed to environmental elements, which can impact its durability and appearance.

Co-Extrusion WPC

Co-extrusion, or second-generation WPC decking, uses an advanced process where a core of wood-plastic composite material is encapsulated by a high-performance polymer shell. This protective layer enhances durability, shields against environmental factors, and improves aesthetics, making co-extrusion WPC a superior option.

Performance and Durability

First-Generation WPC

While first-generation WPC decking offers resistance to rot and insect damage, it has limitations. The unprotected surface is prone to fading, scratching, staining, and moisture absorption. UV exposure can cause color fading, and prolonged moisture contact may lead to swelling or warping. Additionally, mold and mildew growth can occur in damp environments.

Co-Extrusion WPC

Co-extrusion WPC features a polymer cap that provides superior UV and moisture resistance. This protective layer prevents color fading, warping, and mold growth, ensuring the decking maintains its appearance and structural integrity. The capped surface is also resistant to scratches and stains, making it ideal for high-traffic areas and harsh environmental conditions.

Aesthetics and Surface Finish

First-Generation WPC

The exposed wood fibers in first-generation WPC create a natural wood-like appearance. However, this exposure also makes the surface more vulnerable to damage, leading to a decline in aesthetics over time. Color options are often limited, with uniform appearances that lack the variations of natural wood.

Co-Extrusion WPC

Co-extrusion technology allows for realistic wood grain textures and a broader range of color options. The polymer cap mimics the natural patterns and variations of wood, delivering a more authentic and visually appealing look. This enhanced surface finish also provides resistance to fading and staining, ensuring long-lasting beauty.

Maintenance Requirements

First-Generation WPC

First-generation WPC requires regular maintenance to retain its appearance and structural integrity. This includes cleaning to remove mold and mildew, applying sealants to reduce moisture absorption, and addressing surface scratches. Neglecting maintenance can result in accelerated wear and tear.

Co-Extrusion WPC

Co-extrusion WPC significantly reduces maintenance needs. Its protective cap resists mold, stains, and scratches, requiring only occasional cleaning with soap and water. There is no need for sealing, staining, or painting, making it a hassle-free option for homeowners.

Cost Considerations

First-Generation WPC

First-generation WPC is more affordable initially, making it a cost-effective choice for budget-conscious buyers. However, higher maintenance requirements and shorter lifespans may lead to increased long-term costs.

Co-Extrusion WPC

Co-extrusion WPC comes with a higher upfront cost due to its advanced manufacturing and superior materials. However, its lower maintenance needs and extended lifespan can offset this initial investment, providing better value over time.

Environmental Impact

First-Generation WPC

Both first-generation and co-extrusion WPC are made from recycled wood fibers and plastics, contributing to sustainability. However, the shorter lifespan and higher maintenance requirements of first-generation WPC may result in more frequent replacements and resource consumption.

Co-Extrusion WPC

Co-extrusion WPC’s enhanced durability and longevity reduce replacements and resource use, making it a more sustainable choice. Additionally, its reduced need for chemical treatments lowers its environmental footprint.

Explore WPC Options in Vietnam

- Learn more about WPC decking in Vietnam.

- Discover durable WPC cladding solutions.

- Enhance your outdoor spaces with WPC pergolas.

- Secure your property with stylish WPC fencing.

- Explore additional options, such as WPC furniture and other WPC elements.

Conclusion

The evolution from first-generation single-layer WPC to co-extrusion types highlights significant advancements in decking technology. First-generation WPC offers a cost-effective solution with natural aesthetics but requires more maintenance and has a shorter lifespan. In contrast, co-extrusion WPC provides superior durability, improved aesthetics, and lower maintenance needs, making it a preferred choice for homeowners and businesses.

Ready to explore high-quality WPC products? Visit our contact page to get started!